Essential Wiring & Cabling Tips for Safe, Efficient Installs

A commercial electrical installation requires careful planning and execution to ensure safety, efficiency, and long-term reliability. From selecting the appropriate wiring materials to organizing cables for easy maintenance, every aspect of the installation plays a crucial role in the performance of the electrical system. Businesses must adhere to industry standards and regulations to prevent hazards such as electrical fires, connectivity issues, and energy inefficiency. Whether upgrading an existing electrical system or installing wiring in a new facility, following best practices can significantly impact functionality and safety.

Choosing the Right Wiring Type

1. Copper Vs. Aluminum Wiring

Copper wiring is the preferred choice for most commercial applications due to its excellent conductivity, durability, and resistance to heat. It provides better energy efficiency and reduces the risk of electrical failures. However, aluminum wiring is sometimes used for high-voltage applications because it is more affordable and lightweight, though it requires additional precautions to prevent oxidation and loosening over time.

2. Conduit Vs. Open Cable Installations

Electrical conduit provides superior protection for wiring, especially in environments exposed to moisture, extreme temperatures, or physical damage risks. Conduits, whether made of PVC, metal, or flexible materials, shield wires from external threats and improve longevity. Open cable installations, though sometimes used in low-risk environments, lack the same level of protection and can be prone to wear and tear, leading to safety hazards and maintenance issues.

3. Voltage-Specific Wiring

Commercial electrical systems often require different types of wiring for lighting, power distribution, and specialty equipment. High-voltage applications, such as HVAC systems and industrial machinery, need heavy-duty cables with thick insulation, while low-voltage wiring is used for security systems, intercoms, and communication lines. Properly identifying the voltage needs of each circuit ensures efficiency and compliance with electrical codes. Learn more about electrical wiring done by pros, read “Choosing The Right Wiring: Electrical Contractor Tips.”

Proper Conduit Placement

1. Avoiding Obstructions

Electrical conduits should be installed in locations that do not interfere with plumbing, HVAC systems, or structural components. Running conduits through areas with frequent movements, such as loading docks or mechanical rooms, can lead to accidental damage. Strategic conduit placement ensures safety and minimizes the risk of costly repairs.

2. Ensuring Accessibility

Proper conduit placement should allow for easy access during maintenance and upgrades. Installing conduits in walls, ceilings, or underground may require service panels or junction boxes for accessibility. Well-placed access points reduce labor costs when future modifications are needed and simplify troubleshooting.

3. Compliance with Building Codes

Commercial buildings must adhere to strict conduit installation guidelines set by the National Electrical Code (NEC). These regulations dictate conduit sizing, spacing, and material requirements. Failing to comply with these codes can lead to failed inspections, delays, and increased liability risks for businesses.

Network and Data Cabling

1. Seamless Connectivity in Office Settings

Modern businesses rely heavily on stable network connections for communication, file sharing, and cloud-based operations. Using high-quality Ethernet cables, fiber optics, and structured cabling systems ensures reliable internet access and data transmission. Poorly installed cabling can lead to slow speeds, dropped connections, and costly downtime.

2. Shielding Against Interference

Electrical interference from power lines, fluorescent lighting, and industrial machinery can disrupt network signals. Shielded twisted pair (STP) cables and fiber-optic wiring help prevent electromagnetic interference (EMI), ensuring stable connectivity in high-density office environments. Proper grounding and separation from power cables also enhance network performance.

3. Future-Proofing Data Infrastructure

As technology advances, businesses require faster and more efficient network solutions. Installing high-capacity cabling, such as Cat6 or fiber-optic lines, allows for scalability and prevents the need for frequent rewiring. Investing in future-proof network infrastructure ensures smooth integration of new technologies without major disruptions.

Fire-Resistant and Weatherproof Wiring

1. Protecting Electrical Systems in High-Risk Environments

Commercial buildings, particularly industrial facilities and warehouses, must use fire-resistant wiring to minimize the risk of electrical fires. Fire-rated cables have protective coatings that prevent flames from spreading in the event of a fire. These cables are crucial for areas with high heat exposure, such as server rooms or manufacturing plants.

2. Weatherproofing for Outdoor Installations

Outdoor electrical wiring must withstand rain, snow, and extreme temperatures. Weatherproof conduit, corrosion-resistant materials, and insulated connectors help prevent moisture damage and deterioration over time. Failing to use weather-resistant wiring can lead to short circuits, power failures, and increased maintenance costs.

3. Emergency Power and Backup Systems

Installing fire-resistant and weatherproof wiring is essential for backup power systems, such as generators and uninterruptible power supply (UPS) units. These systems ensure uninterrupted operations during power outages or natural disasters, reducing downtime for businesses that rely on constant power availability.

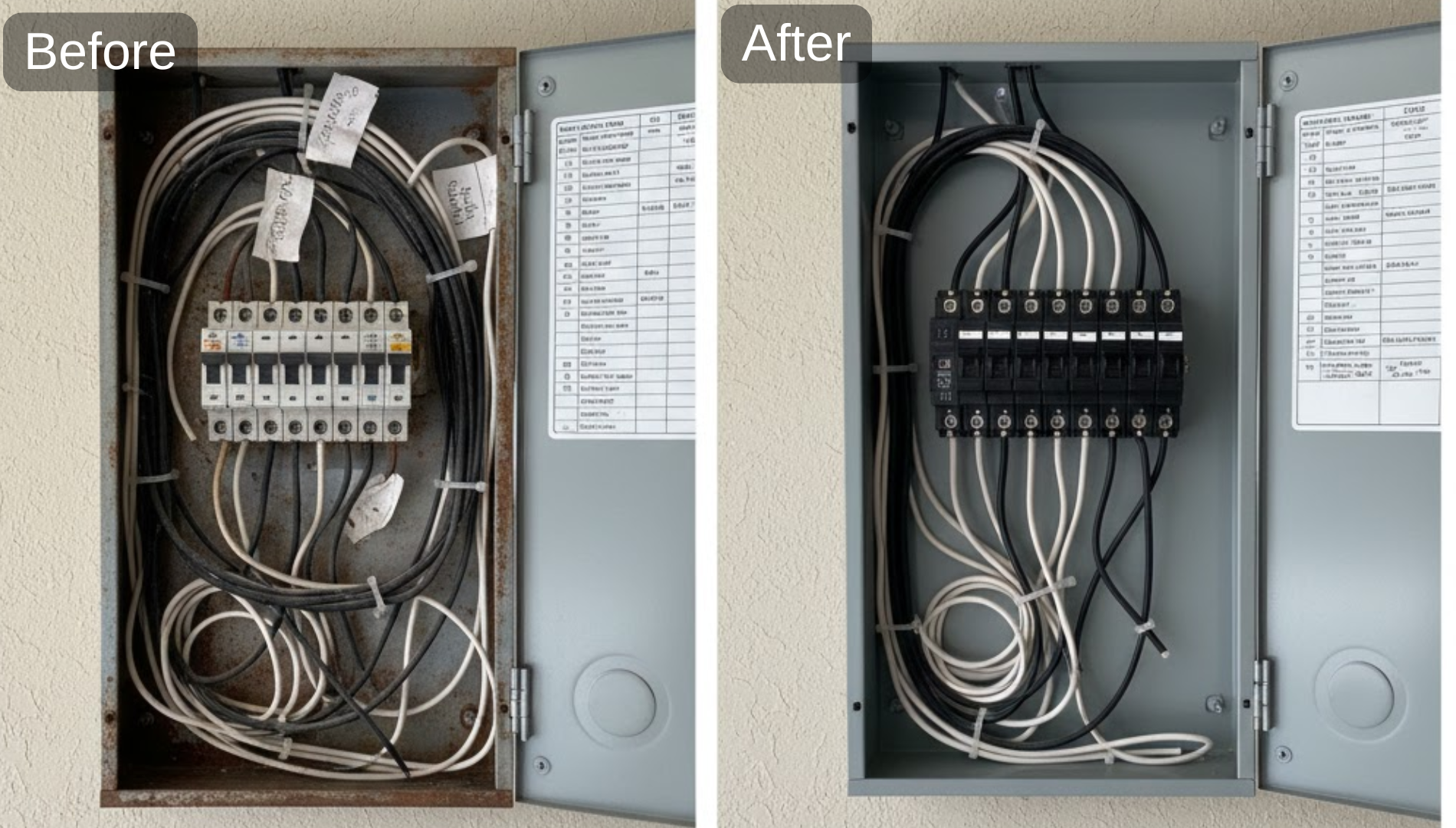

Labeling and Organizing Wires

1. Simplifying Future Maintenance

Properly labeled wiring allows electricians to quickly identify circuits, reducing downtime during repairs and upgrades. Each cable should be marked with voltage ratings, circuit numbers, and destination points. Unlabeled wiring creates confusion, leading to costly troubleshooting and increased safety risks.

2. Using Color-Coded Wires

Standardized color coding helps differentiate between different types of wiring, such as power, lighting, and data cables. Following industry color conventions ensures consistency and makes it easier for electricians to work on electrical systems without errors.

3. Organized Cable Management

Neatly bundling and securing cables prevents tangling and damage. Cable trays, wire ducts, and zip ties help keep wiring organized and protect them from accidental snags or abrasions. Organized wiring improves airflow in electrical rooms and reduces the risk of overheating.

Conclusion

A properly designed commercial electrical installation ensures safety, efficiency, and longevity. Choosing the right wiring, strategically placing conduits, and using high-quality network cabling can prevent electrical issues and optimize business operations. Fire-resistant materials and weatherproof solutions protect against environmental hazards, while proper labeling and organization simplify maintenance. By following best practices, businesses can avoid costly repairs, improve energy efficiency, and ensure compliance with safety regulations. Working with a professional electrician guarantees that all wiring and cabling installations meet industry standards.

A reliable electrical system is key to any successful business.

Nash Electric LLC specializes in commercial electrical installation, ensuring safe, efficient, and code-compliant wiring solutions. Whether you need structured cabling, panel upgrades, or fire-resistant wiring, our team delivers expert services tailored to your needs. Don't risk downtime or safety hazards—let us handle your electrical upgrades with precision and professionalism.

Contact us today for a consultation and power your business with confidence.